Services Completed:

> Initial design review describing the best process option for manufacture.

> Proposal for the gas channel layout and design.

> Recommendation for component design changes to optimise for process.

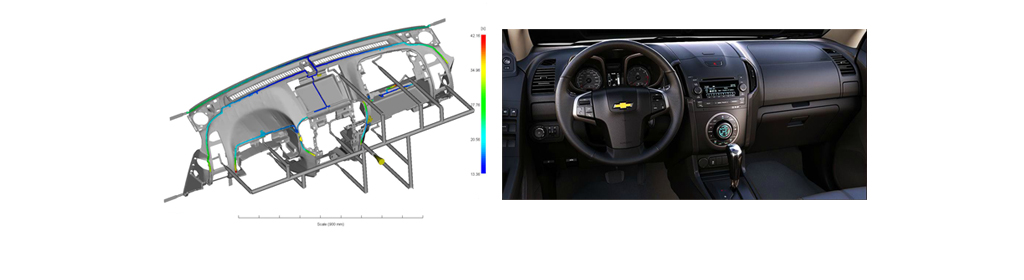

> Initial flow analysis to develop an acceptable plastic filling pattern using 11 sequenced valve gates.

> Gas analysis of the instrument panel as full shot moulding with the use of multiple gas nozzles and overflow wells.

> Presentation of the results and discussions with the Brazilian toolmaker via web conference.

> On-going support during the tool design process.

> Specification of the gas generation and injection equipment required for production.

> Detailed information provided to the toolmaker for plastic gate locations, gas injection nozzle location and design, overflow method and overflow design.

> Process support in Korea at the tool manufacturer for initial trials and tool proving.

> Process support during production trials in Brazil for the moulder.

> Gas injection equipment and process training of the moulders production personnel.

> Gas injection process and design training for the moulders design and development staff.