We offer a flow analysis service using both 2D and 3D analysis programs and quotations are available on request. The quotation can be prepared from 2D drawings and pictures but a 3D model will be required for the analysis.

We can accept the following 3D file formats:

> .stl

> .igs

> .stp (step)

Please contact us for more information.

The analysis service covers:

> Standard injection moulding

> Internal gas injection moulding

- Full shot

- Shot shot

- Overflow wells

> Rapid heating and cooling

An initial flow analysis proposal will include a basic design review of your component. This will highlight the production process of choice and indicate where there may be opportunities to improve the component design.

The EGM process cannot be analysed but an injection moulding analysis should still be complete to optimise the design

The results can also be presented by a member of staff. This is often requested and provides an opportunity for all parties to get together to discuss the approach, provide a detailed understanding of the process and finalise design and tooling details. This visit can be quoted on request.

Analysis Report:

The analysis report usually comes in the form of a PowerPoint presentation that includes both pictures and animations.

The presentation typically includes:

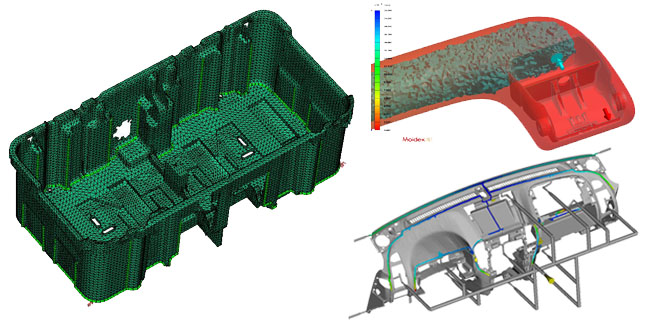

> The meshed model

> The plastic gate locations

> The plastic filling pattern

> Gate sequencing where applicable

> The plastic pressure

> The plastic temperature

> The gas flow during filling and packing

> The shrinkage prediction

> The clamp tonnage prediction

Analysis can also include:

> Shrinkage and warpage

> Cooling and conformal cooling

> Heat and cooling cycles

> Overflow design and dimension

> Gas nozzle locations

> Gas nozzle design

To get a quotation please contact us.